KT500 OnLineMOMS

Online Real-Time Mold Oscillation Monitoring System

Continuous Monitoring for Quality and Process

Continuous Monitoring for Quality and Process

KT500 OnLineMOMS

Online Real-Time Mold Oscillation Monitoring System

Continuous Monitoring for Quality and Process

Continuous Monitoring for Quality and Process

KT500 OnLineMOMS

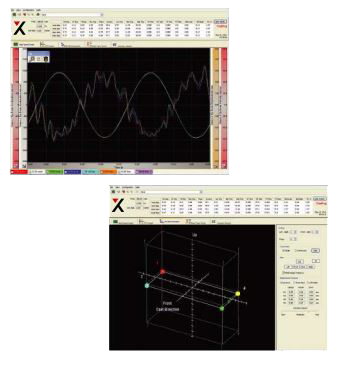

The KT500 OnLineMOMS system integrates caster variable inputs to provide a complete monitoring system for process and mechanical/control analysis of the caster. The system consists of: main control unit with system computer and software; four compact sensors, which are permanently attached to the mold table; and high temperature system cables.

Advantages

- Oscillation speed

- Casting speed

- Mold level

- Tundish temperature

- Tundish slide gate position

- Tundish weight

- Ladle weight

Advantages

Measurements and Calculations

- Rapidly identify old oscillator mechanical/control issues

- Prioritize maintenance of caster mold oscillators

- Compare oscillator performance in noncasting and casting conditions

- Evaluate optimal casting practices

- Evaluate mold lubrication practices

- Up/Down Displacement

- Left/Right Displacement

- Front/Back Displacement

- Residual Displacement

- Phase

- Rise/Fall Ratio

- Low, Medium and High Frequency Vibrations

- Negative Strip Time and Ratio

- Positive Strip Time and Ratio

- Mold Lead

- Friction Index

- Oscillation Mark Depth

Download this product PDF

Importance of Mold Oscillation

M.O.M.S* Technology to Ensure an Optimal Mold/Strand Interface

Achieve product quality, productivity and lower costs with this step-by-step guide.

Assure that your mold oscillation mechanism is operating as designed.

Importance of Mold Oscillation

M.O.M.S* Technology to Ensure an Optimal Mold/Strand Interface

Achieve product quality, productivity and lower costs with this step-by-step guide. Assure that your mold oscillation mechanism is operating as designed.

Whenever You Need Us,

We're Here For You

You can rely on our unsurpassed products, customer support, problem resolution, and extensive on-site training.

Send us a message

Send us a message

Leading the steel industry for a measurable difference

Providing data-driven insights to continuous casting since 1989. Choose Kiss Technologies for a measurable difference.