The Kiss Technologies Blog

The Kiss Technologies Blog

How should a steelmaker look at data for a modern data-driven continuous casting machine?

This blog post covers historical data analysis, real-time monitoring, predictive analytics, machine learning, and data visualization techniques that steelmakers can use to optimize their continuous casting process and stay competitive in the global market. In our...

What data should a steelmaker use for a modern data-driven continuous casting machine?

In recent years, data-driven technologies have revolutionized steelmaking — and the most successful steelmakers are relying on data analytics to optimize their continuous casting process. We previously covered why steelmakers need to be looking at data — but what...

Why You Need Data to Improve Continuous Casting Quality

Improving continuous casting quality and productivity is a high priority for any steel caster. Top steelmakers strive to produce more, higher quality steel in less time and with less downtime. But that’s often easier said than done. This is where data and analytics...

Improving Steel Cast Quality Without Disrupting Productivity

Right now, the steel casting industry is at peak production. Your facility has been running so hard for so long that quality has started to take a hit. Equipment is beginning to fail. The price for steel has increased, but you can't take full advantage of that if your...

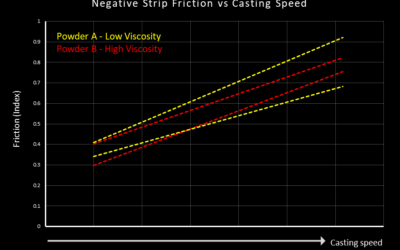

What is Mold Friction?

In continuous casting of steel, improving product quality and preventing breakouts are essential to profitable production. Mold friction analysis is one measurement that can help steel casters better understand constant changes in the continuous casting machine and...

What is Negative Strip Time?

When it comes to the quality of continuous casting, steelmakers know that mold oscillation plays a vital role. One important concept that's often discussed in regards to mold oscillation and continuous casting is negative strip, which is usually expressed as negative...

Acoustic vs Electromagnetic Ladle Slag Detection Systems: What’s the Difference

Steelmakers know that one of the greatest threats to steel production quality is slag carryover from the ladle to the tundish. Traditionally, operators would physically sense the change in vibration at the handles of the ladle shroud manipulator and manually close the...

Economic Benefits of a Ladle Slag Detection System

Ladle slag carryover is a significant concern for steelmakers working to improve the yield and quality of their continuous casting process. For those seeking an effective method to reduce slag carryover, ladle slag detection systems are an attractive option. These...

Welcome to the New Kiss Technologies Website

Kiss Technologies is proud to unveil our new website! Our website now offers helpful information and resources related to Kiss Technologies and features a user-friendly interface and design that more accurately reflects our brand. Our biggest goal with this new site...

Leading the steel industry for a measurable difference

Providing data-driven insights to continuous casting since 1989. Choose Kiss Technologies for a measurable difference.

Leading the steel industry for a measurable difference

Providing data-driven insights to continuous casting since 1989. Choose Kiss Technologies for a measurable difference.