Our Approach

Our Approach

Superior Caster Analytics for Data-Driven Decision Making

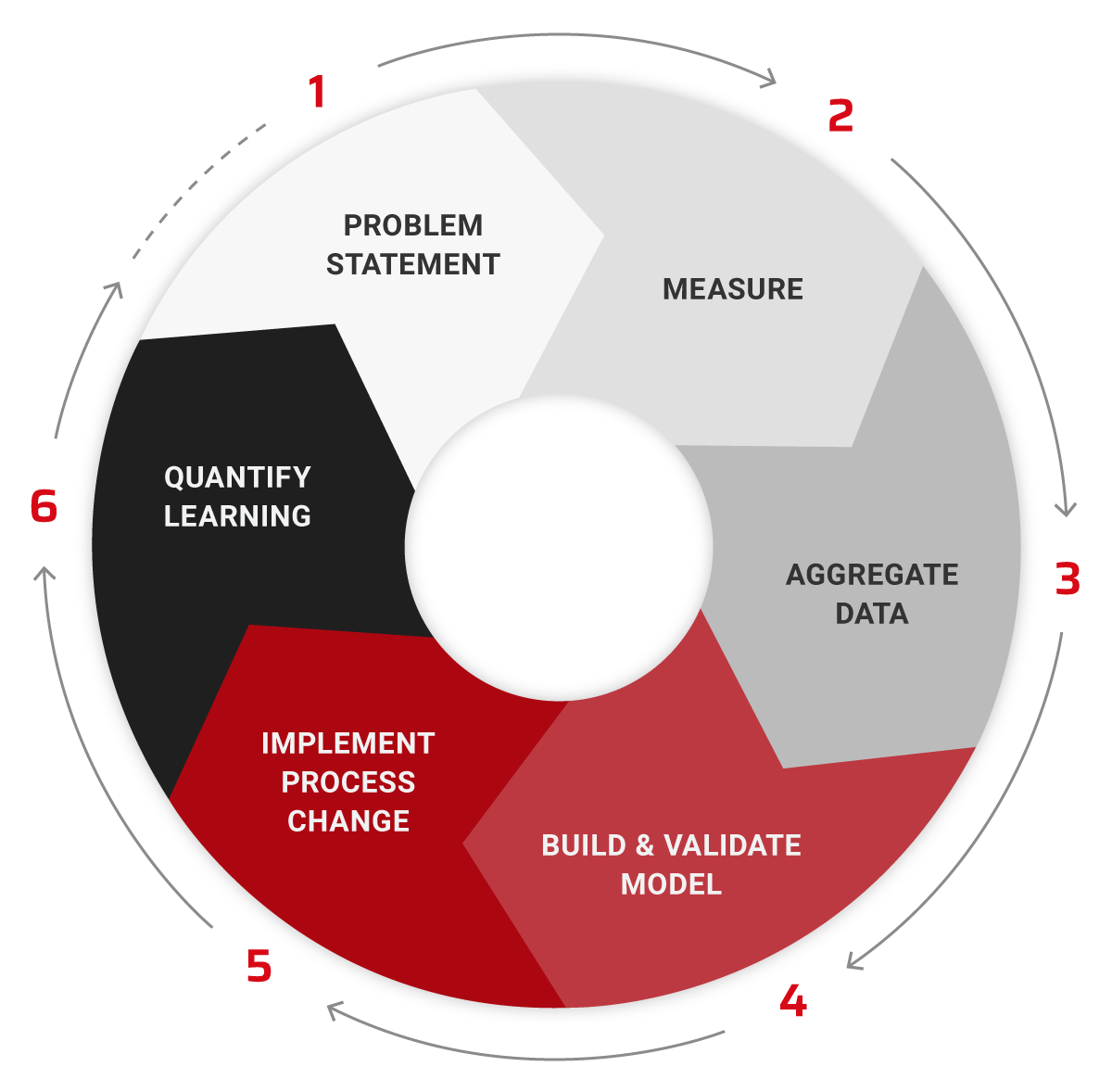

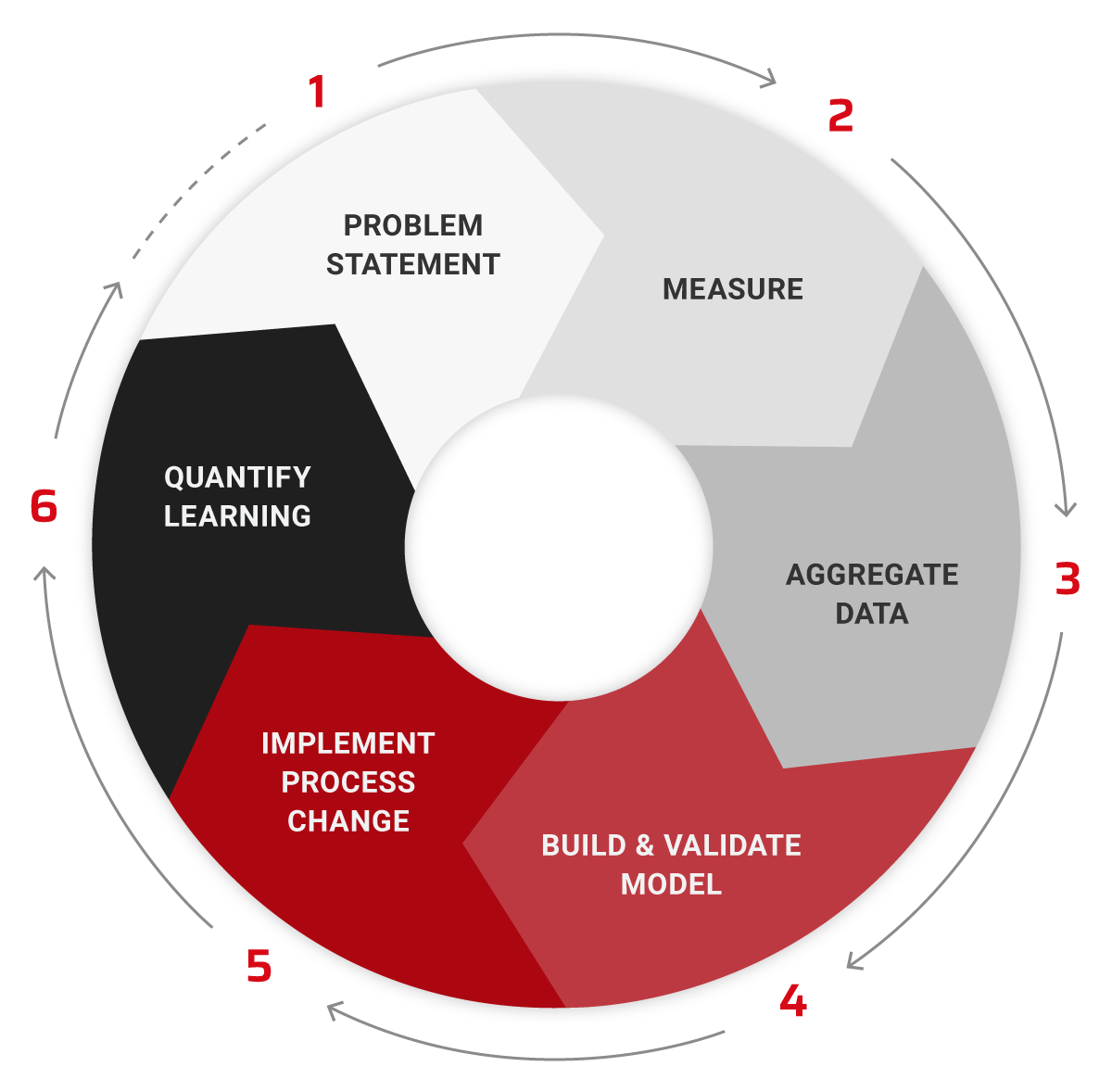

This six-step process wheel is a visual representation of how we make those data-based decisions. From collecting and measuring data to analyzing it for your specific application, we follow each step in the flywheel to develop insights we know will positively improve your casting process. After each insight is implemented, our process wheel keeps turning as we evaluate the impact of those new decisions for continuous improvement.

Superior Caster Analytics for Data-Driven Decision Making

Superior Caster Analytics for Data-Driven Decision Making

This six-step process wheel is a visual representation of how we make those data-based decisions. From collecting and measuring data to analyzing it for your specific application, we follow each step in the flywheel to develop insights we know will positively improve your casting process. After each insight is implemented, our process wheel keeps turning as we evaluate the impact of those new decisions for continuous improvement.

Our Six-Step Approach to Optimizing Your Casting Process

At Kiss Technologies, we take pride in working closely with our clients to learn about their facilities, determine their problems, and deliver comprehensive results through data-based decision making. Here’s what you can expect when you start working with the Kiss Technologies team:

1. Audit

2. Measure Data

3. Manage Data

4. Analyze Data

5. Visualize Data

6. Apply Insights

1. Audit

2. Measure Data

3. Manage Data

4. Analyze Data

5. Visualize Data

6. Apply Insights

1. Audit

We start our process by examining your situation. We take stock of your current casting process and work with you to determine what problems you are experiencing and how we can help. We’ll also look to see what data you have available, and in what form.

Kiss Technologies concludes this step with a complete evaluation of your challenges followed by an identification of opportunities for improvement. We paint a picture of your current casting situation, and we’ll identify key casting goals for the future of your plant.

1. Audit Data

We start our process by examining your situation. We take stock of your current casting process and work with you to determine what problems you are experiencing and how we can help. We’ll also look to see what data you have available, and in what form.

Kiss Technologies concludes this step with a complete evaluation of your challenges followed by an identification of opportunities for improvement. We paint a picture of your current casting situation, and we’ll identify key casting goals for the future of your plant.

2. Measure Data

2. Measure Data

3. Manage Data

With the Kiss Technologies CasterANALYTICS tool in place, we then work to aggregate data for real-time analysis and historical trending. We take data from every source in your plant, including plant processing data, measurement systems, as well as our own measurement systems, and we put it all in one common storage. This affords a big-picture view of your casting process and allows us to apply machine learning and analytics techniques to all data sources simultaneously.

With data managed in one convenient location, we’re able to apply machine learning and analytics techniques to all data sources simultaneously. This affords a bigger picture view of your casting process and enables us to develop insights that benefit your entire production.

3. Manage Data

With the Kiss Technologies CasterANALYTICS tool in place, we then work to aggregate data for real-time analysis and historical trending. We take data from every source in your plant, including plant processing data, measurement systems, as well as our own measurement systems, and we put it all in one common storage. This affords a big-picture view of your casting process and allows us to apply machine learning and analytics techniques to all data sources simultaneously.

With data managed in one convenient location, we’re able to apply machine learning and analytics techniques to all data sources simultaneously. This affords a bigger picture view of your casting process and enables us to develop insights that benefit your entire production.

4. Analyze Data

4. Analyze Data

5. Visualize Data

As Kiss Technologies solutions start to positively impact your plant, our team works hard to ensure it’s all visible and easily accessible to you. We place a high priority on data visibility, which is why our CasterANALYTICS tool allows you to manipulate views into data for your own analysis, and see key data measurements and parameters on one screen. We call this your dashboard. Totally customized to your data, your company, and your preferences, your dashboard offers:

- KT900 3-D and Heat Map Visualizations

- Key casting parameter display

- Shared process insights, from our team to yours

5. Visualize Data

- KT900 3-D and Heat Map Visualizations

- Key casting parameter display

- Shared process insights, from our team to yours

6. Apply Insights

With your custom dashboard set up, and our predictive modeling and machine learning framework running, all the necessary tools are in place to apply insights we’ve developed to optimize your unique casting process. Our CasterANALYTICs outputs, combined with our data engineers’ broad casting experience, offer you the most intuitive insights in steel casting. Those insights are now applied to help hit your target casting conditions and improve your facility’s overall production quality.

From here, our process just keeps going. Our CasterANALYTICS tool will continue collecting data, and our data engineers will continue to develop and apply new insights based on current performance. Continuous reiteration of each step of our unique approach ensures further refinement of the results, putting your facility closer to perfect production with every improvement.

6. Apply Insights

With your custom dashboard set up, and our predictive modeling and machine learning framework running, all the necessary tools are in place to apply insights we’ve developed to optimize your unique casting process. Our CasterANALYTICs outputs, combined with our data engineers’ broad casting experience, offer you the most intuitive insights in steel casting. Those insights are now applied to help hit your target casting conditions and improve your facility’s overall production quality.

From here, our process just keeps going. Our CasterANALYTICS tool will continue collecting data, and our data engineers will continue to develop and apply new insights based on current performance. Continuous reiteration of each step of our unique approach ensures further refinement of the results, putting your facility closer to perfect production with every improvement.

Trust Our Approach

So why choose our process? You can say goodbye to the process of elimination and guesswork. It’s simply ineffective and costly. Because data and analytics is empowering.

Trust Our Approach

So why choose our process? You can say goodbye to the process of elimination and guesswork. It’s simply ineffective and costly. Because data and analytics is empowering.

Importance of Mold Oscillation

M.O.M.S* Technology to Ensure Good Lubrication

Achieve product quality, productivity and lower costs with this step-by-step guide.

Assure that your mold oscillation mechanism is operating as designed.

Importance of Mold Oscillation

M.O.M.S* Technology to Ensure an Optimal Mold/Strand Interface

Achieve product quality, productivity and lower costs with this step-by-step guide. Assure that your mold oscillation mechanism is operating as designed.

Whenever You Need Us,

We're Here For You

You can rely on our unsurpassed products, customer support, problem resolution, and extensive on-site training.

Send us a message

Send us a message

Leading the steel industry for a measurable difference

Providing data-driven insights to continuous casting since 1989. Choose Kiss Technologies for a measurable difference.

Leading the steel industry for a measurable difference

Providing data-driven insights to continuous casting since 1989. Choose Kiss Technologies for a measurable difference.