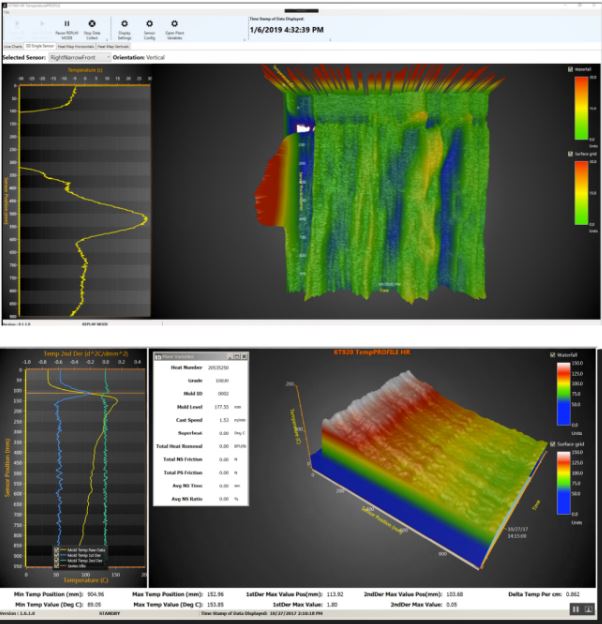

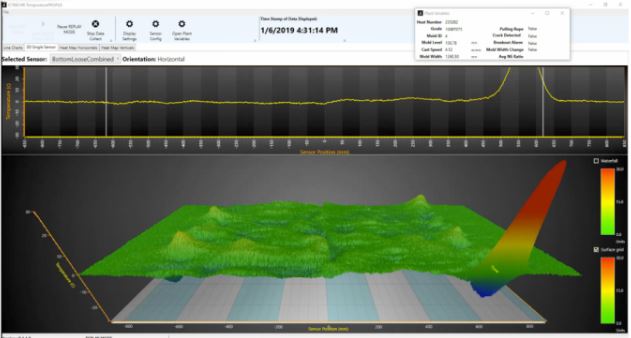

KT900 HR TemperaturePROFILE

High Resolution Fiber Optic Mold Temperature Mapping System

Mold temperature is a primary indicator of the solidifying shell as it moves through the mold. The temperature measurements indicate the condition of lubrication and heat removal which directly relate to steel quality and casting stability. The KT900 System provides accurate breakout prevention capabilities and detects conditions leading to crack formation and surface defects for prevention.

Service Features & Benefits

- High-resolution mold temperature map providing information on the mold flux behavior and solidification process

- Temperature profile display down length of the mold from top to bottom

- Mold level sensing to monitor meniscus behavior

- Accurate hot-spot /cold-spot warnings for breakout, NMI, cracks and surface defects

- Auto-adaptive detection algorithms based on casting models

- Fiber temperature sensors are reusable from mold to mold

- Cost per sensing element less than other sensing technologies

Fiber Optic Sensor Specifications

| Sensing Linear Resolution | 1538 Sensing Elements/Meter |

| Sensing Element Size: | 0.65 mm |

| Measurement Accuracy | +0.1°C |

| Flexible Layout Options | Horizontal and Vertical Orientations |

Download this product PDF

Importance of Mold Oscillation

M.O.M.S* Technology to Ensure an Optimal Mold/Strand Interface

Achieve product quality, productivity and lower costs with this step-by-step guide.

Assure that your mold oscillation mechanism is operating as designed.

Importance of Mold Oscillation

M.O.M.S* Technology to Ensure an Optimal Mold/Strand Interface

Achieve product quality, productivity and lower costs with this step-by-step guide. Assure that your mold oscillation mechanism is operating as designed.

Whenever You Need Us,

We're Here For You

You can rely on our unsurpassed products, customer support, problem resolution, and extensive on-site training.

Send us a message

Send us a message

Leading the steel industry for a measurable difference

Providing data-driven insights to continuous casting since 1989. Choose Kiss Technologies for a measurable difference.

Leading the steel industry for a measurable difference

Providing data-driven insights to continuous casting since 1989. Choose Kiss Technologies for a measurable difference.