KT310 / KT320 TriACCEL

For Motion and Vibration Measurement

KT310 / KT320 TriACCEL

Tri-Axial Accelerometer Sensor

For Motion and Vibration Measurement

Specifications

Two Models for better low end accuracy/higher top end range.

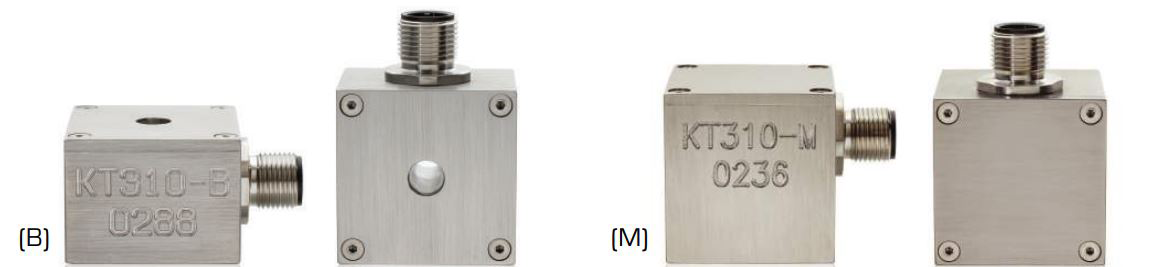

KT310 and KT320 come in either Bolt-on (B) or Magnetic (M) configurations

KT310

KT320

Voltage Resolution:

Displacement Accuracy:

Frequency Range:

Filtering:

Power:

Axis Alignment:

Overload:

Temperature:

Mounting:

Dimensions:

2.20 V/G (4,557 mm/sec²/VDC)

+/-0.013mm

0.0 to 500 Hz

Internal low pass anti-aliasing set to 500 Hz

5.00 VDC

+/-0.10º

20,000 G

-40/+125ºC

Bolt-on or Magnetic

35mm x 35mm x 33mm

1.10 V/G (8,915 mm/sec²/VDC)

+/-0.025mm

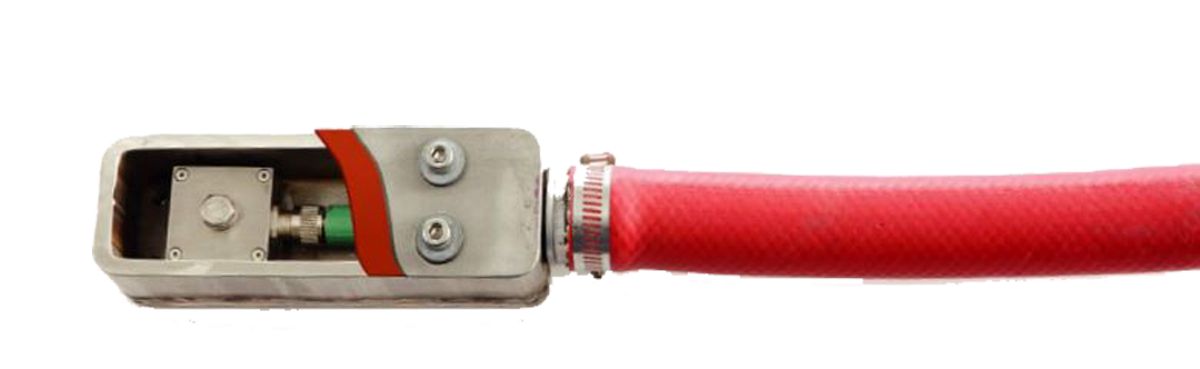

Protective Enclosure for KT310 or KT320 Bolt-On Version

Sensor and Cable Protection

Since 1989, we’ve been offering proven technologies and robust products designed to survive continuous operation—24 hours a day, 7 days a week—within the harsh conditions of the steelmaking environment. Made from stainless steel, the KT310B sensors are used in the KT500 OnLineMOMS system and are securely bolted into a protective steel enclosure that is welded onto the oscillator. This enclosure features a sealed lid that protects against water or fluids, as well as an elongated exit neck for secure clamping of hydraulic hose—shielding the sensor cable out of containment and further preventing fluids from entering. Pyro-sleeve covering can be added for increased fire protection. The enclosure’s cable clamp prevents damage from excessive stress by providing strain relief for the sensor cable. Properly installed, the KT310 sensors and cables provide years of reliable service on the oscillators, and the design allows sensors and cables to be easily removed and reinstalled for maintenance and calibration.

Download this product PDF

Importance of Mold Oscillation

M.O.M.S* Technology to Ensure an Optimal Mold/Strand Interface

Achieve product quality, productivity and lower costs with this step-by-step guide.

Assure that your mold oscillation mechanism is operating as designed.

Importance of Mold Oscillation

M.O.M.S* Technology to Ensure an Optimal Mold/Strand Interface

Achieve product quality, productivity and lower costs with this step-by-step guide. Assure that your mold oscillation mechanism is operating as designed.

Whenever You Need Us,

We're Here For You

You can rely on our unsurpassed products, customer support, problem resolution, and extensive on-site training.

Send us a message

Send us a message

Leading the steel industry for a measurable difference

Providing data-driven insights to continuous casting since 1989. Choose Kiss Technologies for a measurable difference.

Leading the steel industry for a measurable difference

Providing data-driven insights to continuous casting since 1989. Choose Kiss Technologies for a measurable difference.