KT500F Mold Friction

Real-Time Mold Friction Calculation for Process and Quality Control

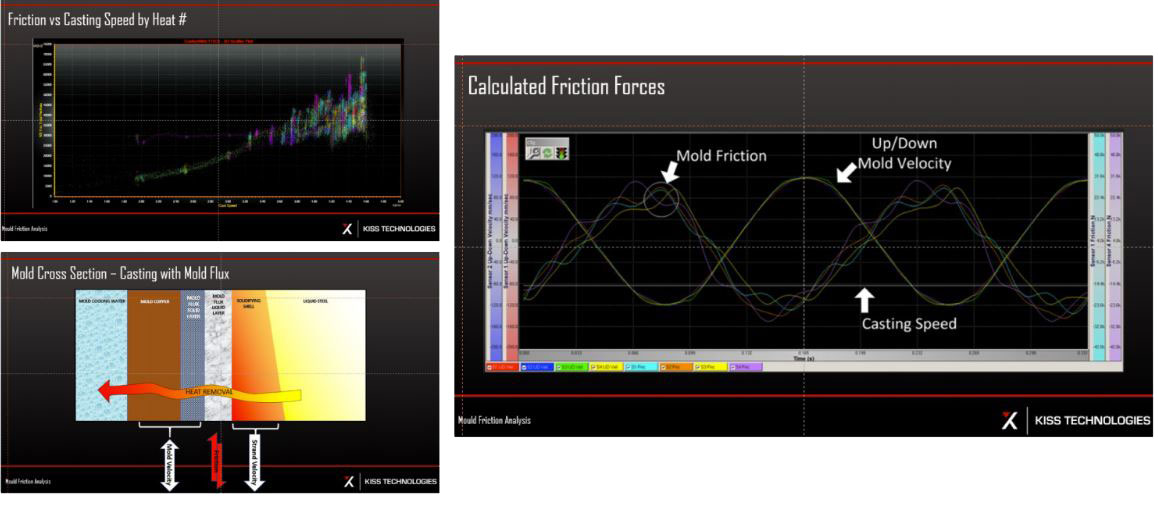

The KT500F OnLineMOMS System with Friction adds mold/strand friction measurements to the primary casting parameters generated by the standard KT500 System. Friction is a key indicator of casting process and conditions directly inside the mold. Coupled with the KT500 accelerometer based oscillation data, mold friction provides a deeper layer of insight into casting stability, flux performance, conditions affecting quality, and potential casting events leading to a loss of production.

Additional Insights to the KT500

- Friction characterization by steel grade

- Best practices for hard-to-cast steel grades

- Real-time feedback for ne tuning casting

parameters - Evaluate mold lubrication practices

- Assess mold-strand gap conditions

- Mold ux and heat removal characterization

Features

- Full integration of process variables with the Kiss Technologies systems

- Preventive alarms to avoid potential decoupling or sticker conditions

- Available for hydraulic and mechanical oscillators

- Install on new and existing KT500 OnLineMOMS Systems

- Kiss Technologies’ engineering analysis available with CasterANALYTICS

Download this product PDF

Importance of Mold Oscillation

M.O.M.S* Technology to Ensure an Optimal Mold/Strand Interface

Achieve product quality, productivity and lower costs with this step-by-step guide.

Assure that your mold oscillation mechanism is operating as designed.

Achieve product quality, productivity and lower costs with this step-by-step guide.

Assure that your mold oscillation mechanism is operating as designed.

Importance of Mold Oscillation

M.O.M.S* Technology to Ensure an Optimal Mold/Strand Interface

Achieve product quality, productivity and lower costs with this step-by-step guide. Assure that your mold oscillation mechanism is operating as designed.

Whenever You Need Us,

We're Here For You

You can rely on our unsurpassed products, customer support, problem resolution, and extensive on-site training.

Send us a message

Send us a message

Leading the steel industry for a measurable difference

Providing data-driven insights to continuous casting since 1989. Choose Kiss Technologies for a measurable difference.

Leading the steel industry for a measurable difference

Providing data-driven insights to continuous casting since 1989. Choose Kiss Technologies for a measurable difference.