Publications

Technical Publications

Mold Oscillation Monitoring – Operational & Maintenance Tool

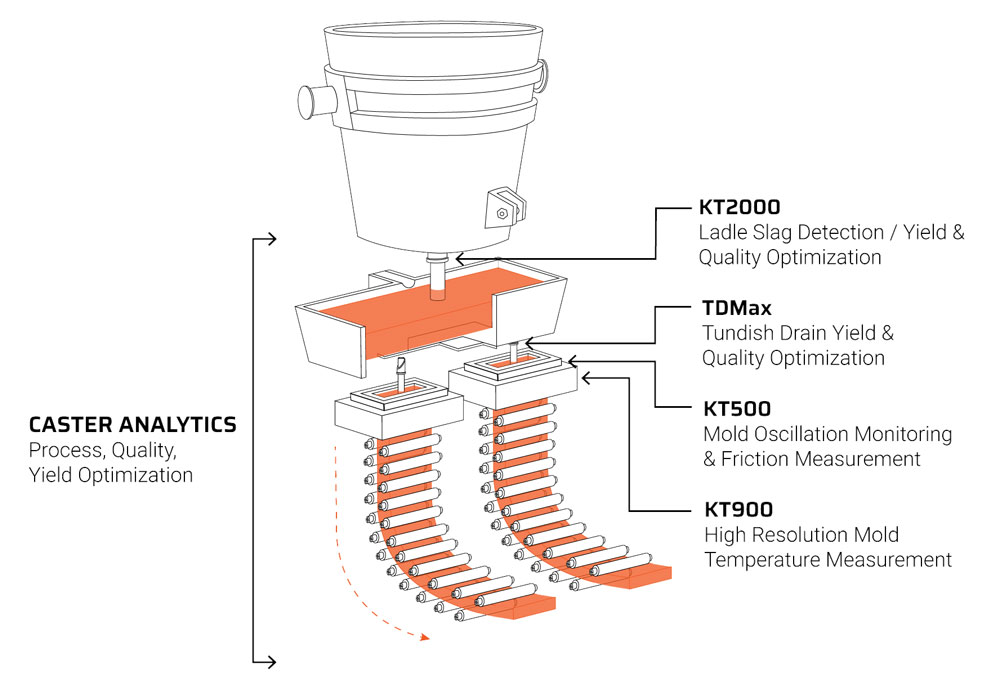

As competition increases within the steel

industry, it is crucial for organizations to operate with the utmost efficiency and yield high quality products. The mold oscillator is a key component in the steel making process and its malfunction directly impacts the surface quality of the product. For either a value added or low-grade commodity producer, a mold oscillation monitoring system can reduce operating and maintenance costs typically incurred for premature equipment replacement.

Read More.

Tri-Axial Mold Oscillation Monitoring System

A portable accelerometer-based system was developed, tested, and is being used to monitor mold oscillation on the two slab casters at Bethlehem Steel’s Burns Harbor Plant. The system employs tri-axial accelerometers to measure mold acceleration in the vertical direction and in the two horizontal directions perpendicular to the mold narrow and broad faces. From the acceleration signals, which are gathered by a portable computer, the mold velocity and displacement are calculated in the three directions using a frequency analysis technique.

Read More.

Ladle Slag Detection System Startup at ISPAT Mexicana

Ispat Mexicana (IMEXSA) is one of the world’s largest slab suppliers. Customer’s quality demand for the cold

rolled exposed application and the API grades for line pipe has become increasingly stringent. To meet this challenge, IMEXSA has installed a vibration-type ladle slag detector, which has significantly improved the quality of the slabs by enhancing steel cleanliness.

Consistently optimized yield, reduced tundish refractory costs, expanded sequence length, and reduced nozzle clogging was also obtained.

Read More.

Ladle Slag Detection System Startup

Republic Technologies International, Incorporated Canton facility was able to concurrently improve quality and increase yield of bearing quality steels using a noncontact slag “prediction” system. Quality verification was achieved utilizing extensive microsonic testing and a pressurized pour box for visual inspection.

Read More.

Whenever You Need Us,

We're Here For You

You can rely on our unsurpassed products, customer support, problem resolution, and extensive on-site training.

Send us a message

Send us a message

Leading the steel industry for a measurable difference

Providing data-driven insights to continuous casting since 1989. Choose Kiss Technologies for a measurable difference.

Leading the steel industry for a measurable difference

Providing data-driven insights to continuous casting since 1989. Choose Kiss Technologies for a measurable difference.