KT2000 GEN2:

AI-Powered Slag Detection

for Real-Time Yield Control

Smarter Slag Detection. Real-Time Yield Control.

The KT2000 GEN2 turns slag detection into an active yield optimization tool—helping operators balance clean-steel recovery, tundish protection, and cost efficiency at every heat. Built on advanced artificial intelligence and machine learning, it transforms detection from a reactive safeguard into a predictive control variable.

AI + Machine Learning:

The New Standard in Ladle Slag Detection

Instead of reacting to slag after contamination occurs, GEN2 predicts and prevents it—ensuring precision, consistency, and confidence heat after heat.

The Problem:

Inconsistent Detection and Lost Yield

Traditional electromagnetic and early acoustic systems often struggled in noisy, high-interference environments.

They were reactive, not preventive—detecting slag only after it entered the tundish. The result?

- Unreliable readings from plant vibration and hydraulic noise

- False alarms or missed events caused by signal drift

- Inconsistent ladle closure decisions that cost operators valuable clean steel

The Solution:

KT2000 GEN2

The KT2000 GEN2 eliminates these long-standing challenges through machine learning that continuously adapts to plant conditions.

It’s both noise-proof and ladle weight-smart—ensuring accuracy in every environment.

- Plant Noise Immunity – Machine-learning filters distinguish real slag signatures from vibration, hydraulic, and electrical noise—virtually eliminating false alarms.

2. Weight Independence – Adaptive correction algorithms maintain accuracy even when scale data drifts or becomes unreliable.

The result: clear, repeatable detection at the exact moment it matters most—during the final seconds of the pour.

Why Upgrade to KT2000 GEN2

AI-Powered Detection

Filters out plant noise and signal drift to ensure consistent accuracy.

Operator Empowerment

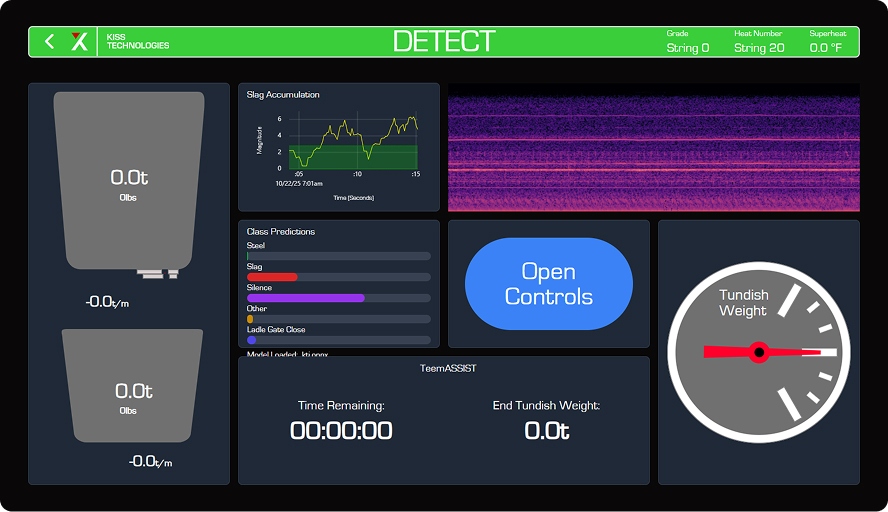

TeemASSIST™ delivers real-time ladle-end guidance for confident, precise draining.

Connected Intelligence

Monitor, analyze, and optimize every heat through GEN2’s cloud ecosystem.

Measurable ROI

Increase yield, cut rework, and achieve cleaner steel with lower operating costs.

How Machine Learning Improves Detection Reliability

GEN2 continually learns from your process. It analyzes acoustic signatures, compares them with historical trends, and automatically corrects for anomalies.

The outcome: higher accuracy, cleaner steel, and fewer costly interruptions—no matter the noise level or ladle condition.

GEN2 Ecosystem:

The Infrastructure Behind Smarter Casting

The KT2000 GEN2 isn’t just a sensor—it’s a complete infrastructure that connects acoustic detection, AI-driven analytics, and operator tools into one continuous improvement loop.

- Live Dashboards – Monitor KPIs, uptime, and performance issues instantly.

- Heat Review – Visualize acoustic signals, listen to recorded data, and correlate with ladle/tundish parameters.

- Model Training & Validation – A/B test new ML configurations before deployment.

- Performance Reports – Track detection rates, yield metrics, and operator impact.

- Cloud Integration – Secure data upload, model updates, and remote optimization.

- Data Studio – Analyze historical heats, verify ROI, and collaborate directly with Kiss Technologies experts.

- Ticketing & Support – Seamless issue resolution and continuous improvement tracking.

Economic Benefits of

AI-Powered Slag Detection

KT2000 GEN2 translates data accuracy into economic advantage.

1. Increased Yield

4. Immune to Noise Anomalies

2. Reduced Rework

5. Continuous Improvement Through Data

3. Operator Efficiency

6. Does Not Require a Ladle Weight Signal

1. Increased Yield

Recover more clean steel instead of leaving value behind.

2. Reduced Rework

Prevent inclusions before they cause costly reprocessing.

3. Operator Efficiency

TeemASSIST™ ensures consistent, repeatable ladle-end decisions.

4. Immune to Noise Anomalies

Delivers accurate detection even in noisy environments.

5. Continuous Improvement Through Data

Machine learning refines accuracy over time for sustained ROI.

6. Does Not Require a Ladle Weight Signal

Simplifies setup; no external inputs or recalibration are needed.

Backed by Enterprise

The Kiss Technologies engineering and data science team support every GEN2 installation, ensuring measurable value from day one.

From education and installation to ongoing model optimization, our experts deliver the insight and support needed for continuous casting excellence.

Looking Ahead: AI as the Standard for Continuous Casting

AI-driven slag detection is quickly becoming the industry benchmark.

Steelmakers using GEN2 are no longer reacting to slag carryover—they’re controlling yield in real time, improving uptime, and setting new standards for process consistency.

The Result: Cleaner steel. Higher yield. Measurable cost savings at every heat.

Optimize Your Continuous

Casting with KT2000 GEN2

The KT2000 GEN2 isn’t just an upgrade—it’s the new standard in ladle slag detection.

By combining AI, operator-focused tools, and a connected ecosystem, it ensures higher yields, cleaner steel, and lasting process stability.

Chat With an Expert

Explore the Science Behind GEN2

Curious how AI transforms slag detection into yield control?