YieldANALYTICS

The Right Balance for Maximum Steel Yield and Quality

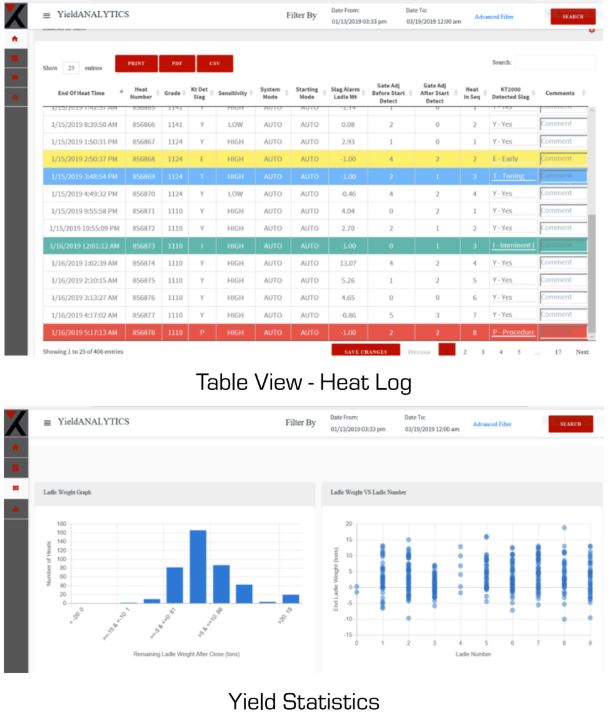

Data from each heat is captured in a powerful database with advanced search capabilities for on-demand review by detection, steel weights, heats, shift, grade and other criteria. With this information at hand, cases of degraded performance and reduced yield are quickly identified for corrective action. Kiss process experts present recommendations on operator practices and end-of-ladle process to guarantee maximum yield. Real-time notifications on system conditions and faults are sent directly to designated plant personnel so adverse conditions are immediately addressed.

Steel Plant personnel are busy with day-to-day operations. Yield ANALYTICS supplements your resources and KT2000 LadleSLAG System with Kiss process expertise for maximum yield and clean steel.

Service Features

- Monthly and quarterly subscription levels available

- Detection and steel yield performance statistics and recommendations

- Tuning adjustments to maintain high detection rate

- YieldANALYTICS Database and Search Engine

- On-demand heat log, detection rate and yield statistics graphs

- Web app and desktop versions

- Web meetings to discuss priorities, process and actions.

- Real-time system fault and error notifications.

- Steel Yield Calculator

.

Download this product PDF

Importance of Mold Oscillation

M.O.M.S* Technology to Ensure an Optimal Mold/Strand Interface

Achieve product quality, productivity and lower costs with this step-by-step guide.

Assure that your mold oscillation mechanism is operating as designed.

Importance of Mold Oscillation

M.O.M.S* Technology to Ensure an Optimal Mold/Strand Interface

Achieve product quality, productivity and lower costs with this step-by-step guide. Assure that your mold oscillation mechanism is operating as designed.

Whenever You Need Us,

We're Here For You

You can rely on our unsurpassed products, customer support, problem resolution, and extensive on-site training.

Send us a message

Send us a message

Leading the steel industry for a measurable difference

Providing data-driven insights to continuous casting since 1989. Choose Kiss Technologies for a measurable difference.

Leading the steel industry for a measurable difference

Providing data-driven insights to continuous casting since 1989. Choose Kiss Technologies for a measurable difference.