by Tovi Kiss | Dec 11, 2025 | Kiss Technologies, Ladle Slag Detection Systems

Among the many variables that affect casting yield, the ladle-to-tundish transition remains one of the most difficult to control. In modern steelmaking, continuous casting operations face constant pressure to improve efficiency and reduce loss. Rising energy costs,...

by Tovi Kiss | Jul 31, 2025 | Kiss Technologies

Continuous steel casting is one of the most interconnected and complex operations in steel production. While major equipment failures are rare and usually obvious, it’s often the subtle, undetected changes in process behavior—oscillation drift, cooling variation,...

by Tovi Kiss | Apr 11, 2025 | Kiss Technologies

Why Measured Friction Matters: Choosing the Right Caster Monitoring System In continuous casting, real-time insights into mold conditions are essential for achieving optimal performance and product quality. One critical parameter steelmakers use is mold...

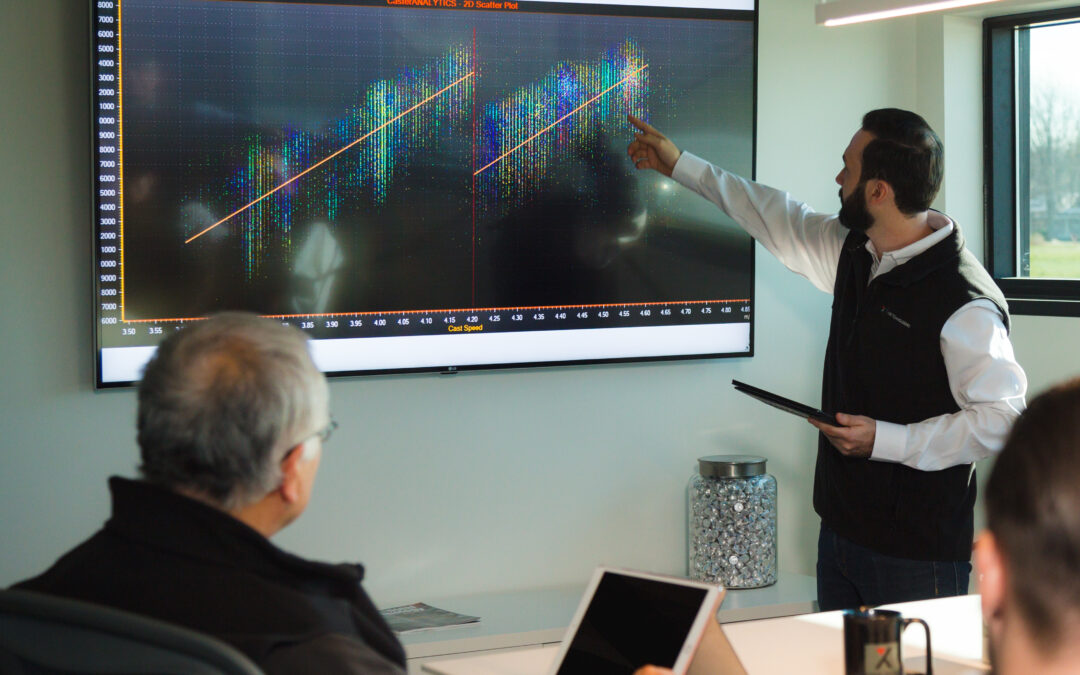

by Michael Kiss | May 16, 2023 | Kiss Technologies

This blog post covers historical data analysis, real-time monitoring, predictive analytics, machine learning, and data visualization techniques that steelmakers can use to optimize their continuous casting process and stay competitive in the global market. In our...

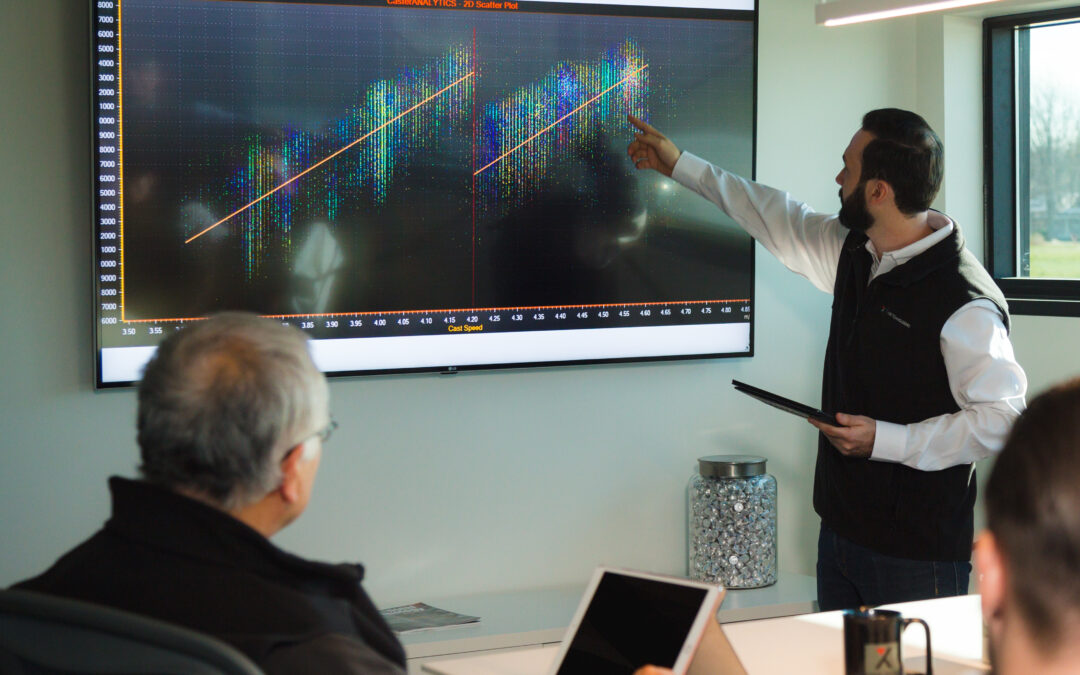

by Michael Kiss | May 5, 2023 | Kiss Technologies

In recent years, data-driven technologies have revolutionized steelmaking — and the most successful steelmakers are relying on data analytics to optimize their continuous casting process. We previously covered why steelmakers need to be looking at data — but what...

by Michael Kiss | Oct 31, 2022 | Kiss Technologies

Improving continuous casting quality and productivity is a high priority for any steel caster. Top steelmakers strive to produce more, higher quality steel in less time and with less downtime. But that’s often easier said than done. This is where data and analytics...